Detailed explanation of Mini-LED direct display C0B package solder paste

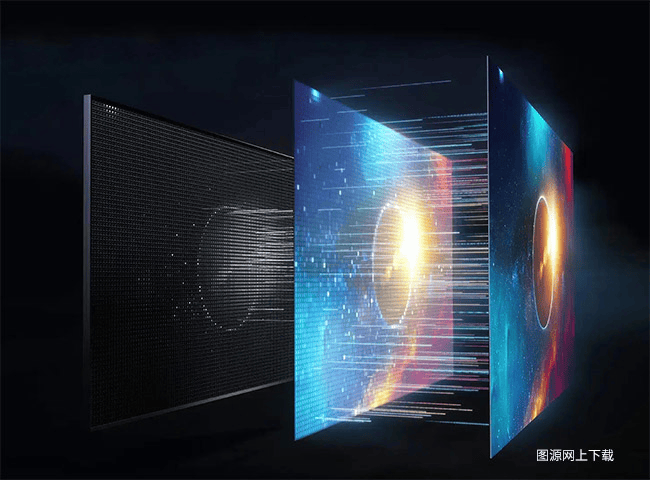

Mini-LED direct display technology adopts COB (Chip on Board) package, which can achieve high density, high contrast and high brightness display effect.In the COB packaging process, solder paste, as a key connecting material, plays a crucial role in soldering quality and reliability.The following is a detailed analysis of Mini-LED direct display COB package solder paste:

1. Features of Mini-LED direct display COB package

High-density package: Mini-LED chip size is small, the number of chips per unit area is large, the packaging process is required to have high precision and high density.

High reliability: COB package will be directly welded to the chip on the substrate, reducing the number of welding points and connecting wires, improving product reliability.

High brightness and contrast: Through fine control of the light emission of each LED chip, it achieves high brightness and high contrast display effect.

2. the role of solder paste in COB packaging

Connection: solder paste melts during the reflow process, firmly connecting the LED chip with the substrate to form an electrical and mechanical connection.

展开全文Heat dissipation: the alloy composition of the solder paste has good thermal conductivity, help the LED chip heat conduction to the substrate, improve thermal efficiency.

Protective effect: solder paste after welding the formation of solder joints can protect the LED chip from the erosion of the external environment, improve the service life of the product.

3. Mini-LED direct display COB package solder paste features

High precision printing: in order to meet the Mini-LED chip high-density packaging requirements, solder paste needs to have good 3·21·12iu'y'f'd's, can be accurately filled into the tiny pad gap, under the tin consistency requirements.

Low viscosity and philanthropy: the viscosity of the paste needs to be moderate, not only in the printing process to maintain good fluidity, but also in the printing of the shape of the rapid recovery, to prevent chip drift.Thixotropy helps the paste to maintain a stable shape during the printing process.

Lead-free environmental protection: With the increasingly strict environmental regulations, lead-free solder paste has become the mainstream of the market.Lead-free solder paste not only meets the environmental requirements, but also improves the reliability and stability of soldering.

Good soldering performance: Solder paste needs to be able to quickly melt and evenly wet the pad and chip surface during reflow soldering to form high-quality solder joints.Residue after welding should be as little as possible, and no corrosive to the substrate, solder paste particle size model is generally T6 (5-15um) or T7 (2-11um), ultra-micro solder powder particle size is small, large surface area, ultra-micro solder paste is more prone to tin beads.

4. Mini-LED direct display COB package solder paste application cases

At present, there are a number of manufacturers in the market for Mini-LED direct COB package launched a special solder paste.For example:

Heraeus: launched the Welco series of solder paste, including Welco AP519, Welco LED120 and other models.These pastes have high precision printability, low viscosity and good soldering performance for Mini-LED and Micro-LED packages.

Fitech: Fitech, which specialises in microelectronic packaging materials, has launched the Fitech FTP-0176 and FTP-3057 series of high-precision solder pastes.This series adopts ultra-fine solder powder (particle size T6, T7 models) and lead-free environmental protection formula, with excellent printing and filling ability and low residue characteristics, the solder joints formed after soldering are full and uniform, with excellent thermal conductivity.Its products have been successfully applied to Mini/Micro LED direct display ultra-high definition large screen, high-end TV and commercial display field, through the combination of material science and precision technology, to ensure the welding stability and long-term reliability under high-density packaging.

AIM: As one of the world's leading solder suppliers, AIM has also launched dedicated solder and flux products for the Mini-LED market to meet different applications and needs.

5. Summary

Mini-LED direct display COB encapsulation solder paste as a key material connecting the LED chip and the substrate, the welding quality and reliability plays a vital role.With the continuous development of Mini-LED technology, the performance requirements of solder paste are also getting higher and higher.In the future, with the continuous progress of material science and encapsulation technology, the performance of Mini-LED direct COB encapsulation solder paste will be further improved to provide more solid support for the development of Mini-LED technology.